Operational Update:

June 9th, 2021

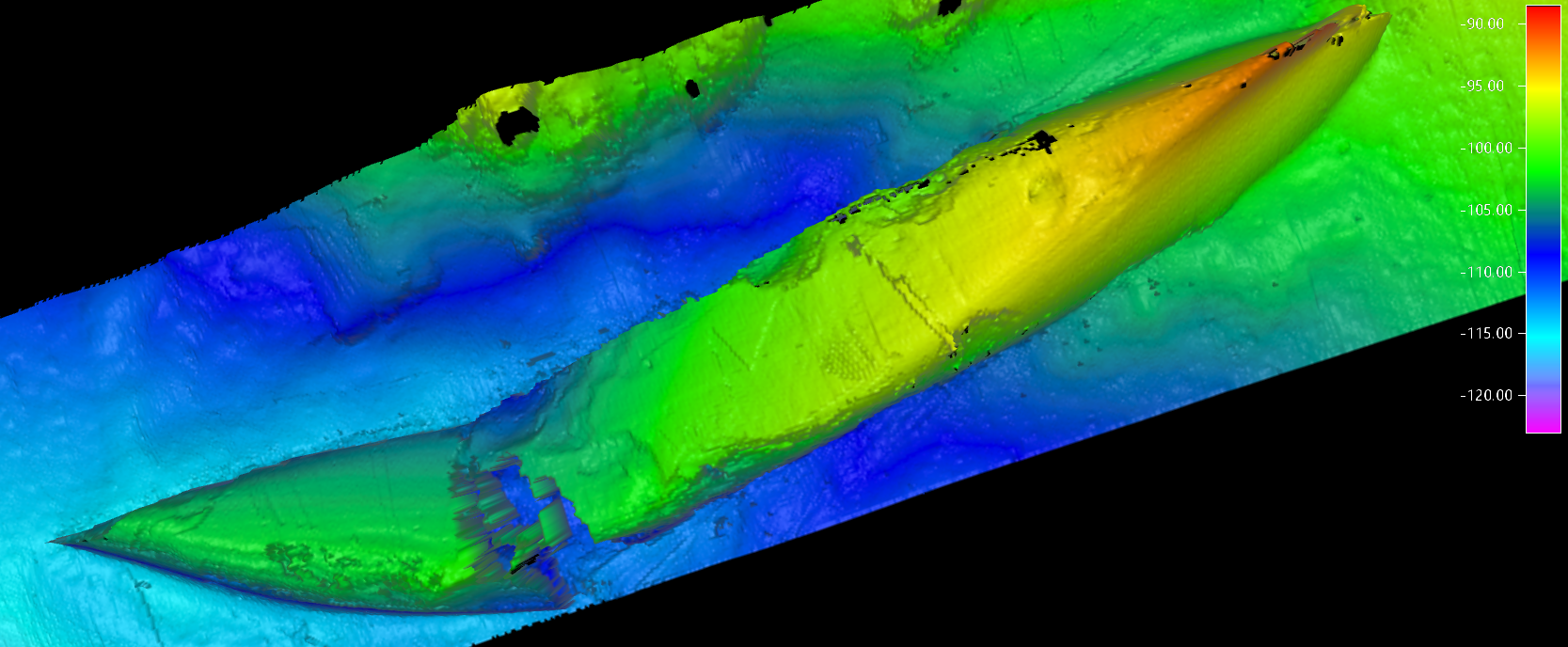

The results of the Technical Assessment confirmed a significant quantity of fuel still on board the MV Schiedyk, and determined that immediate action to remove bulk fuel is necessary to protect Nootka Sound. Unified Command, comprised of the Canadian Coast Guard, BC Ministry of Environment and Climate Change Strategy and the Mowachaht/Muchalaht First Nation, are preparing for the removal of bulk fuel from the vessel in June.

Results of the Technical Assessment

Tanks located and confirmed to contain fuel:

- Two tanks containing Heavy Fuel Oil (sometimes known as Bunker C)

- One tank with Marine Diesel Oil

- One tank with mixed oil product

- The engine compartment of the ship was also found to contain oil product

The amount of fuel is estimated to be approximately 147 cubic metres (147,000 litres) based on the total volume of the tanks. However, that amount may be less if the internal tank walls have been compressed by water pressure.

An assessment of the hull found:

- An 11 metre long gash and significant damage on the starboard side of the ship (previously known) was confirmed as the most serious breach in the vessel.

- The hull has extensive minor damage and it appears that the vessel may have rolled on its port side and slid deeper into Zuciarte Channel at some point.

- The thickness of steel in the hull is 16-18mm thick. Plans from the shipyard indicate the hull was 22mm thick when the ship was built in 1948. This is good news as the integrity of the hull can mean a lower risk when drilling into the tanks during the bulk oil recovery phase.

A temporary patch was applied to slow the release of oil:

- A “submar mat” made of thick rubber and about 15m x 5m was placed over the 11m gash in the hull to slow or stop the current flow of oil.

- Rare earth magnets were applied to hold the mat in place on the hull, sand bags were laid around the perimeter, and large cement filled “mattresses” weighing 1500k were lowered over the patch to hold it in place.

- Unified Command had hoped the patch would stop the oil leak as a temporary measure, however while the patch was successful in reducing the amount upwelling, crews continue to see oil on the water.

How bulk oil will be removed from the MV Schiedyk

Resolve Marine will use a process called “hot tapping” to pump the ship’s tanks. Hot tapping is a well known, cost effective, and lower risk method of removing bulk oil. And while it isn’t possible to remove all oil residue from the sunken vessel, the hot tap process will significantly reduce the volume of fuel in the tanks so it is no longer a serious risk to pollute the marine environment.

- Holes will be carefully drilled into the hull of the vessel to access the fuel tanks.

- Once the holes are drilled, hot water generated on the Atlantic Condor will be pumped into the tanks containing the Heavy Fuel Oil. This will increase the temperature of the oil and enable it to flow more easily.

- The oil-water mixture will then be pumped to the surface. On deck the oil will be separated from the water; the oil will be stored in containers for safe disposal later, and the water will be reused in the operation.

- The two tanks containing Heavy Fuel Oil pose the highest risk and will be pumped out first.

- Diesel Fuel Oil isn’t as thick and will not require heating to transfer the tank contents.

- Water will continue to be pumped into the tanks until the recovered product contains a minimum amount of oil or diesel.

Addressing risk during Bulk Oil Removal

During the operation to remove bulk oil from the MV Schiedyk, there is a small risk of a larger release of oil. Of course this risk is already present simply because of the amount of fuel currently sitting in the tanks. This is why Unified Command had decided to proceed with oil removal as soon as possible.

Similar to preparations for the Technical Assessment, Unified Command is prepared for, and has added the following resources at the site to monitor the bulk oil removal operation and respond if required:

- 34 response personnel on site, as well as additional personnel working in the virtual Incident Command Post.

- 7 Pollution Response Vessels crewed by specially trained Environmental Response personnel from Coast Guard and the Western Canada Marine Response Corporation (WCMRC).

- 2 support vessels, 1 safety vessel, and 3 barges to stage equipment such as extra boom.

- 5,392 metres of boom deployed around the wreck site and to protect sensitive areas; 4,938 metres of boom staged near the site in case additional boom is required.

- 3 High Speed Sweep System units and 5 skimmers staged nearby.

- In addition to visual observations from vessel crews, drone and NASP overflights will be deployed to monitor the amount of oil on the water during the operation.

- Environmental monitors from the Mowachaht/Muchalaht First Nation will be actively monitoring the operation and area.

- The DFO Marine Mammal Team will be on the water to monitor marine mammals.

- Bird deterrents are in place near the containment boom and wildlife observers from Focus Wildlife will be on the water and actively monitoring the area. An oiled wildlife trailer will be on site in the event an animal becomes oiled during the operation and requires cleaning.

- DFO has deployed drifter buoys to monitor current speed and direction and Environment and Climate Change Canada is providing trajectory modelling so crews can act proactively in the event of a larger release of oi.

- Shoreline Clean-up Assessment Technique teams are on stand-by to survey the shoreline to ensure protection boom is doing its job.

Work is scheduled to begin in mid June and is expected to take several weeks, depending on weather.